So, what to use? Ball Mill, Conches or Refiners.

Well, if you are me and I had a ton of money, I would like all three !

And it would be wonderful and beautiful and the chocolate would taste heavenly.

But let’s just come down to reality and think rationally.

Ball Mills in itself, specially the industrial version, cost a ton of money.

Conches a lot more.

And Refiners are just out of this world, or dare I say heavenly.

To get the most out of the machine that you are going to use depends a lot on the type of products (Raw materials) that you will be using, your process flow and the end product you are going to produce. (Moulding, paste etc.)

But why do we need a ball mill or a conche or a refiner for that matter in the production of chocolate or chocolate based products?

The need for Ball Mills/Conches/Refiners

As discussed in an earlier post(read it here), chocolate is basically a suspension in which cocoa particles along with sugar particles are coated with fat and the movement of these particles creates the flowability of the chocolate.

Once the cocoa beans are roasted, they have to be crushed/grinded in smaller particles sizes or microns, so that the cocoa particles can be ground down to appropriate sizes and coated with fat. This process can happen with a crushing action, shearing action or grinding action.

Here are the following reasons why the ball mill/conche/refiner is required in a chocolate manufacturing process:-

- Particle Size Reduction :- The particles sizes are made smaller so that they can be coated homogenously with fat.

- Deodorisation :- Removal of unwanted odours from the chocolate.

- Reducing the moisture content

- Developing the flavour

Now to achieve this, either a heavy load can be used, high shear for small duration or low shear for long duration and heat.

On their own, Ball Mills/Conches/Refiners do most of the above tasks pretty good but when used together in a continuous line, they can greatly enhance the quality and the flavour of the end product.

So, that being out of the way, we can concentrate again on what type of machine to use in your chocolate manufacturing needs.

Let’s dive in then.

A brief description

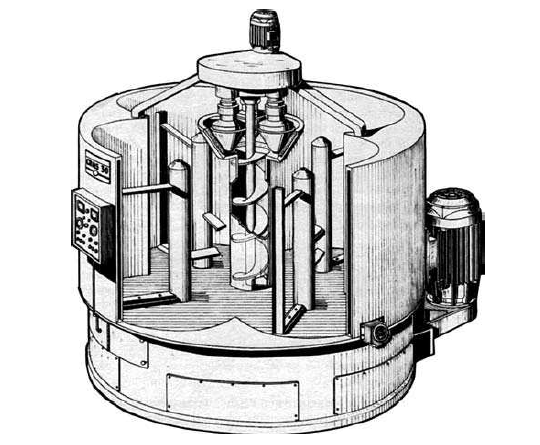

Ball Mills :- Ball mills are basically vertical/horizontal cylindrical containers which have steel balls of 6 – 8 mm, in which an agitator (may be with scrapper) would be present. The heavy load of the balls, the rotating motion of the stirrer and the constant recirculation which happens, with itself or storage tanks present in line(a continuous ball mill as shown in the above image) create a crushing/grinding, homogenising, and taste development cycle.

Conches :- A long term kneading process during which the flavour is developed, the mass is deodorised of the volatile odours and the excess water is evaporated with the help of fins, blades and heat, resulting in high shear.

Refiners :- Again a long term process, in which the micron size is reduced, taste is developed, the mass is deodorised and the water evaporated with help of rollers, creating thin films and the process of high shear.

Well , what should I use then ?

As told earlier, it depends on the type of product you are dealing in.

If most of the chocolate product that you are going to manufacture down the line are compound based(that is majority of Cocoa Butter is substituted with a compatible fat) , you are good to go with a Ball Mill system , with storage tanks and a premix.

Even in a pretty large scale chocolate factory using quantities of pure chocolate and compound chocolate, for most intent and purposes, a continuous ball mill will give you the particle size required, the flavour you need and the texture for your chocolate products.

If the chocolate products you are manufacturing are more cocoa butter based, it would depend on the end product. So, if the end product qualities have to be flowability, less viscosity, you can use a conche.

If the end product that you are manufacturing has to maintain a snap ability , the crunch and the mouthfeel, you can use a roll refiner.(2 roll, 3 roll, 5 roll)

So, but, then what about the cost part of machines?

Yes, so, if you are starting out, better use a ball mill for small batches. As and when the scaling happens, you can procure the conches and the roll refiners.

You see even installing a continuous ball mill consumes time and lots of power. In itself they are pretty easy to maintain but still an experienced skilled person is required to do so.

As you move to a conche, the moving parts are increased, the power is increased and a scheduled maintenance is not an easy task to do.

As you move further refiners are whole together another level where you would require a skilled person to just to run the machine and tend to it. Even a small miscalculation of gap between the rollers can totally mess up your end product. In today’s time more and more automation options are available on the Refiners, but then still those are a cost to you.!

So, please do your research, study and choose wisely, because these machines are going to be with you for a long time.

We would love to help you in your chocolate manufacturing needs regarding Ball Mills/Conches/Refiners.

3 thoughts on “Chocolate Making Equipment: Ball Mills, Conches, Refiners – Which one is Right for You ?”