In an earlier article, “Understanding Fats in Your Chocolate- What you need to Know?” we explained about the various types of Fat that are used in manufacturing of chocolates, but we skipped upon a key point as to how the amount, type of fat increases or decreases the viscosity of chocolates.

Well, in this article we are going to try to understand the behavior of chocolate viscosity with the changing amount or type of fat added. It would help a lot if you would go and read our earlier article The importance of viscosity in chocolates, as it would create a good platform for the discussions we are about to have in this article.

Let us first look at cocoa butter, a fat.

Polymorphism of Cocoa Butter

Fats, chemically known as triglycerides, consist of three fatty acids bonded to a glycerin molecule. In most cases, fats form crystals that exhibit various polymorphs—different molecular arrangements or structures with the same chemical composition. For fats containing a small number of triglycerides, such as cocoa butter (composed of SOS, POP, SOP triglycerides; where S represents stearic acid, P represents palmitic acid, and O represents oleic acid), researchers have identified up to six distinct polymorphs, namely ,![]()

The formation of various crystal types relies on the compatibility of molecules in terms of their shape (referred to as steric factors) and energy. Additionally, the type of crystals formed is influenced by the temperature or temperature gradients to which they are exposed, as well as the duration of the crystallization process. Higher temperatures and longer crystallization times result in denser and more precisely ordered molecular arrangements. In other words, the individual molecules can pack more closely together, leading to higher crystal density.

We will focus here on the steric ability of the molecules, that is the ability to fit together because of shape.

Fitting Together

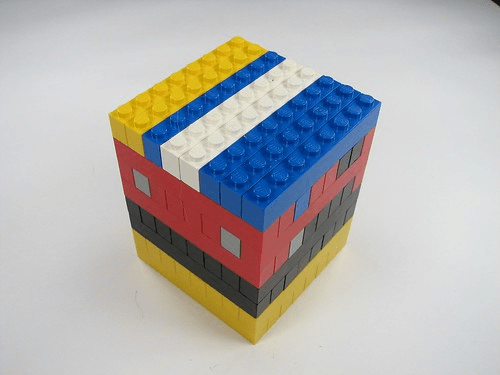

Let’s imagine a chain of Legos, neatly packed and intermeshed with each other. When they are disturbed, they are separated and as the cooling starts, they take the shape of whatever is easily possible.

But our aim is to have a shape which is most stable and prone to further ups and downs in temperature. So, we agitate it, mix it, until we achieve the best possible shape which is stable.

In the case of chocolate, it is the Beta-5 structure which, as regarded by the industry is the most stable to temperature variations, and has good shelf life.

Now let’s imagine we introduce another type of Lego which is totally different from the type and shape of Lego which was existing from before. As the medium reaches to stability, there will be formations, but they will not be stable. However much we temper or tamper the system again. As the system is not very stable, it will take the place of what would have been a stable system and hinder its progress also, essentially jamming the whole system to a halt.

And that’s how the viscosity of the chocolate increases if the extra fat which is being used does not have a similar molecular structure of triglycerides.

Now imagine instead, we introduce another Lego, which is like the type and shape of Lego being used from before. It would give rise to formation of more stable structures, requiring less of space and the medium.

This is how the viscosity of the system is controlled when the vegetable fat being used has similar molecular structure to that of cocoa butter.

To summarize, fats which have the molecular structure of triglycerides like cocoa butter will make the viscosity less, make the chocolate smoother and essentially behave as Cocoa Butter Replacers. Oh! That is a new word. CBR. How did we come to that? Well, it was smooth, wasn’t it?

How much Fat, but?

Now let’s look at the amount of fat being used. If the similar structure fat being used is added extra, the viscosity will decrease and if dissimilar structure fat is added extra, the viscosity will increase. That wasn’t so hard, was it?

A warning

There is a small caveat though. You see, fat coats the sugar and cocoa particles, and the rest fat gets used up as the medium in which those particles float, thereby creating flow. But the particles themselves would have some limitations as to how much they can be coated with fat.

At first, when there is very little coating on the particles, as the fat coats them, the viscosity will drastically increase. As the limits of fat coating are reached, more and more fat is being left for medium and the viscosity will start to decrease.

So, do keep in mind while manufacturing of chocolate as to how much each individual fat can be added to your chocolate recipe.

Conclusion

Please keep in mind that apart from the fats being used, it also depends on the actual recipe, the machines being used and the actual time of preparation and the time after that.

We hope that this article has given you some idea as to how the fats affect the viscosity of chocolates.

In a future article we will discuss about the CBE’s, the CBR’s and other fat variants which are used to enhance the chocolate feel.

2 thoughts on “Understanding Fats in Your Chocolate- Part 2”