There’s something undeniably delightful about the combination of rich, velvety chocolate and the crunchy texture of nuts. Chocolate-coated nuts,also known as dragees, have long been a beloved treat enjoyed by people all around the world. Whether it’s the classic pairing of almonds and dark chocolate or the playful blend of cashews and milk chocolate, these delectable treats offer a symphony of flavors that tantalize the taste buds.

How to make and steps involved–

Chocolate coated nuts are made from the process known as panning. Panning was developed first for use in pharmaceutical industry for use in coated bitter medicines with gold, silver, or sugar. When the use of sugar started taking up, the use of panning was further pushed into the confectionery and the chocolate industry.

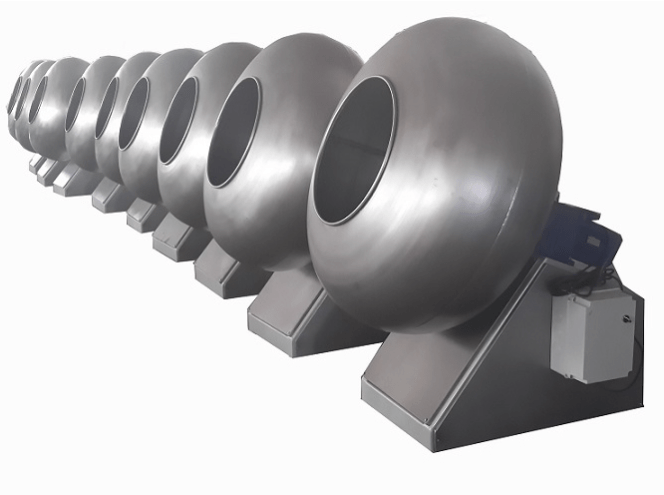

There’s a wide range of equipment available, ranging from a few kilos to 3 tonnes. You can find all sorts of pans, from round to tulip-shaped ones, as well as semi-automatic belt coaters and fully automated self-contained units. But here’s the thing: the basic steps for achieving a great panned product in chocolate, compound, or yogurt coating have remained the same over the years.

Steps involved in Making Dragees-

Center selection

You’ve got plenty of options for centers when it comes to chocolate coating. Natural centers are quite popular, especially if you’re not part of a sweet manufacturing facility.

Some manufactured centers need immediate treatment to maintain their quality or to be ready for coating before they start to deteriorate.

The centers should have a slightly rounded shape with no sharp edges to ensure a smooth and evenly coated product.

Coating nuts like almonds, peanuts, and cashews can be a bit tricky because they have their own challenges. Almonds, for example, tend to have sharp edges that result in uncoated areas. Roasted peanuts may split, causing some “doubles” due to their concave split area. Cashews often have a blank underside due to their natural curve.

Center preparation

This step is crucial in pan-coating. Poorly prepared centers can lead to deformed products, oil/fat migration that ruins the surface, or a lack of grip for the chocolate coating.

This step goes by various names in the industry like sub-coating, gumming, isolating, and stabilizing. The purpose of these processes is to ensure the centers are in good shape for coating. However, if you’ve got well-selected centers like dry roasted nuts or free-flowing raisins with low water content, you may not need these additional steps.

Gumming

In gumming, a wetting mass containing colloids and drying powder is used.

Starch- or dextrin-based wetting masses are preferred nowadays, but gum Arabic and gelatin are also great options. This process helps round off any irregularities and ridges on the centers, especially natural products that are not pan-friendly.

The syrup used should have around 40-50% solids and a high glucose content for proper sticking and to prevent sugar crystallization.

The pans are filled with centers, and the liquid is poured over them as they roll around, ensuring they get wet quickly.

The right amount of liquid is crucial; too little can leave uncoated spots, while too much can cause lumps and excessive dusting. Powder is added quickly to separate the pieces easily. The process is repeated several times, drying the centers overnight between each layer.

Isolating

Some centers contain oils or fats that are not compatible with the chocolate coating.

Isolating is necessary to prevent oil migration and maintain the integrity of the chocolate. Gelatin works well as a continuous film, but gum Arabic is also used. The isolating process is similar to gumming.

Stabilizing

Fragile centers need stabilization to prevent them from breaking during the early stages of panning.

Techniques like wetting with high glucose starch syrup or using a low-viscosity, high-fat chocolate can help stabilize them.

The treated centers are dried overnight before applying the chocolate coating.

What recipes to use?

Well it depends on the end products you are rying to achieve and the type of center you have selected. For example when using a compound chocolate for coating your centers, keep in mind that the oil which is released from the center is compatible with the oil/fat used in making the compound chocolate.

A general rule of thumb is to use a coating as below:-

For sugar syrup- 1:0.25 ratio of sugar and water

For gum Arabic solution :- 0.25:0.25 ratio of water to gum Arabic.

Both can be prepared separately and when prepared, can be mixed together which can be put on the center nuts.

Please note that the recipe mentioned above can be modified as according to the selection of center , the type of chocolate being used and the thickness of coating required.

Machines to use

As mentioned above Panning machines are available in various shape and sizes, manual to fully automatic.

A simple panning machine can be procured from your local chocolate machine manufacturer and in many cases they can be customised. Contact us if you need panning machine and customised solutions.

Frequent issues and troubleshooting:-

Chocolate not sticking to the center

Various reasons can lead to the chocolate not sticking to the center which include but are not limited to –

- Center not prepared correctly that is the center is too rough and not smooth

- The gumming method is not done properly

- The chocolate used is not of correct viscosity (Read our previous article on Viscosity in Chocolates)

Cracking developed on the chocolate coat

Again there can be many reasons but the primary reasons can be

- The chocolate used is not of correct viscosity

- The setting of coating has not been given enough time

- The chocolate amount is too less

- The center is not of proper shape

Bloom development on the coat

The primary reason of bloom development on the chocolate coating is the fact that the oil released from the center has migrated to the chocolate and replaced the cocoa butter present which surfaces as chocolate bloom. The cure is to first use the correct ingredients and if that’s not possible, deposit an extra layer of the water syrup gum Arabic solution.

Chocolate coating not shiny enough

This can be the due to the fact that after coating the polishing solutions has not been applied properly or not given enough to set.

In a future post we will discuss about chocolate centers with sugar coating which are a delight in itself.

I hope that this article has been of some help in your dragee manufacturing needs.