The world of chocolate manufacturing is a delicious and complex one, where precision, innovation, and artistry converge. One of the pivotal pieces of equipment that has transformed the chocolate and confectionery industry is the chocolate ball mill. In a previous article we discussed about what is the right machinery to use, ball mill conche or roll refiner, read it here- Chocolate Making Equipment: Ball Mills, Conches, Refiners – Which one is Right for You ? In this article, we will explore the use of chocolate ball mills in the chocolate and confectionery industry, how to use them effectively, the benefits they offer, common problems that can arise, and how to troubleshoot them.

Chocolate Ball Mills: A Brief Overview

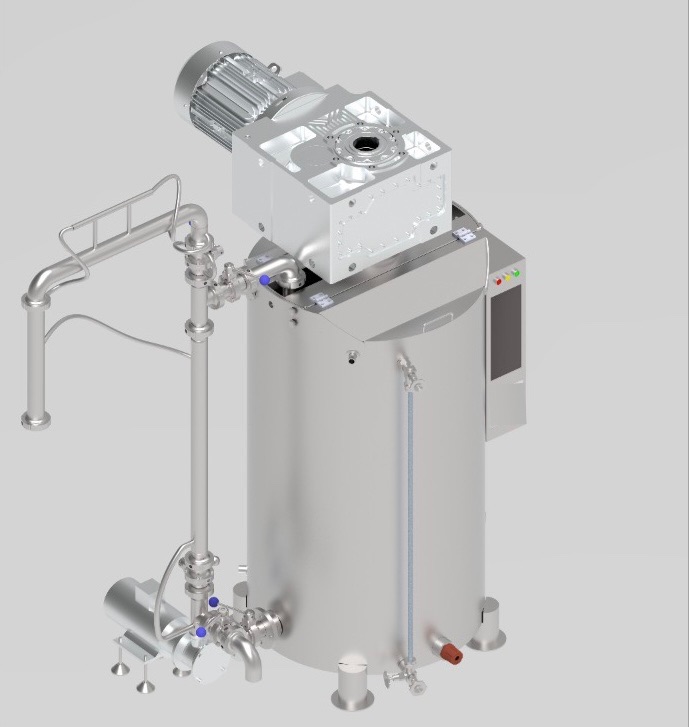

A chocolate ball mill is a specialized piece of machinery designed for the purpose of refining cocoa liquor or chocolate mass. These ball mills are used to produce finely textured, smooth, and consistent chocolate products, ensuring that the final chocolate is of the highest quality. The key components of a chocolate ball mill include a vessel, a rotating agitator/scrapper, grinding balls, and a temperature control system.

How to Use Chocolate Ball Mills

Using a chocolate ball mill effectively requires a well-defined process and understanding of its various components. Here’s a step-by-step guide on how to use chocolate ball mills:

Ingredients Preparation:

Begin by preparing the cocoa liquor or chocolate mass. This is typically a combination of cocoa beans, sugar, milk powder (if making milk chocolate), and any additional ingredients for flavour or texture. Alternatively, ingredients can be loaded into the premix or ball mill directly.

Loading the Ball Mill:

Carefully load the chocolate ball mill with the prepared ingredients. Ensure that the vessel is clean and dry to prevent contamination. The quantity loaded will depend on the capacity of the machine and the desired batch size.

Grinding Process:

Start the machine, allowing the rotating agitator to spin. Simultaneously, the grinding balls inside the vessel begin to move. The movement of the balls and the rotation of the vessel help break down the chocolate mass, ensuring a consistent and smooth texture. This refining process can take several hours, depending on the desired fineness, aroma and flavour.

Temperature Control:

Maintaining the right temperature during the refining process is critical. Chocolate is highly sensitive to temperature, and controlling it ensures proper crystallization. Most chocolate ball mills come equipped with a temperature control system that allows you to heat or cool the chocolate mass as needed.

Monitoring:

Regularly monitor the refining process, checking the texture and taste of the chocolate. Use of gauge micron meter is suggested. Adjust the grinding time and temperature as necessary to achieve the desired quality and flavour.

End of Refining:

Once the chocolate mass reaches the desired fineness, stop the machine. It’s essential to have the final product tested and approved before further processing, such as tempering or molding.

Benefits of Using Chocolate Ball Mills

Chocolate ball mills offer a range of benefits to the chocolate and confectionery manufacturing industry, making them an important piece of equipment for many manufacturers. Some of the key advantages include:

Consistency and Texture:

Chocolate ball mills ensure a consistent and smooth texture in the final product. This uniformity is essential in producing high-quality chocolates, whether in the form of bars, pralines, or truffles.

Improved Flavour Development:

The grinding process in the ball mill helps in flavour development. It allows for the release of volatile compounds, contributing to a well-rounded and developed chocolate flavour. The release of volatile compounds also depends on the time taken during refining.

Efficient Particle Size Reduction:

Chocolate ball mills are highly effective at reducing the particle size of cocoa mass, resulting in better dispersion of cocoa particles within the mixture. This leads to a more even and smoother texture as more and more fat is coated on to the cocoa particles.

Temperature Control:

The built-in temperature control system in ball mills enables precise regulation of the chocolate’s temperature during refining. This is crucial for achieving the desired crystalline structure and shine in the final product.

Versatility:

Chocolate ball mills can be used for various types of chocolates, including dark, milk, and white chocolate. They are also suitable for refining compounds and nut pastes used in praline fillings.

Time Efficiency:

The grinding process in chocolate ball mills is typically faster than traditional refining methods, reducing production time and increasing efficiency.

Common Problems and Troubleshooting

Despite their many advantages, chocolate ball mills are not immune to problems and challenges that may arise during operation. Here are some common issues that chocolatiers and manufacturers may encounter and how to troubleshoot them:

Overheating:

Problem: The chocolate mass overheats during refining, leading to fat bloom and a gritty texture in the final product.

Solution: Check and adjust the temperature control system. Ensure that it is accurately maintaining the desired temperature. Reduce the grinding time or decrease the load if necessary.

Inconsistent Texture:

Problem: The chocolate does not achieve the desired smoothness, resulting in an uneven texture.

Solution: Extend the grinding time if needed, and ensure that the grinding balls are evenly distributed within the vessel. You may also need to refine the recipe to achieve the desired texture. Also, the balls wear out over time and usage. It is beneficial to check the ball data from your ball mill supplier and replace with new balls if necessary.

Blockages and Clogging:

Problem: The machine experiences blockages due to the accumulation of chocolate or other ingredients.

Solution: Periodically stop the machine to scrape the sides and bottom of the vessel to prevent blockages. Ensure that ingredients are added in the correct order and gradually to avoid clogging.

Uneven Grinding Balls:

Problem: The grinding balls may wear unevenly or become misshapen, affecting the quality of the chocolate.

Solution: Regularly inspect and replace grinding balls as needed to maintain their shape and size. Proper maintenance of the machine can help prevent this issue.

Noise and Vibration:

Problem: Unusual noise or excessive vibration during operation.

Solution: Check for loose or damaged parts, such as bearings or drive belts. Tighten any loose components, and if the problem persists, consult the manufacturer for a more in-depth inspection.

Conclusion

Chocolate ball mills have revolutionized the chocolate and confectionery manufacturing industry by providing an efficient and reliable method for refining cocoa mass into high-quality chocolate products. These machines offer consistent texture, improved flavour development, and precise temperature control, making them an essential tool for chocolatiers and confectionery manufacturers.

While chocolate ball mills come with a range of benefits, it’s important to be aware of common issues that may arise during operation. Regular maintenance, monitoring, and troubleshooting can help ensure the continued smooth operation of these machines, resulting in exceptional chocolate creations that delight the palates of consumers around the world.

In the ever-evolving world of chocolate manufacturing, the chocolate ball mill stands as a testament to the industry’s dedication to quality, precision, and the pursuit of perfection in every delectable bite of chocolate.

Book a 1 hour Technical Strategy Session today.

For India:- Rs. 2499/-

Outside India:- USD 39/-

Very nice text , informative and for knowledge updation for all chocolate makers and users 👍👍

LikeLike

Thank you for your kind words Mr Umare. It is our endeavour to spread the knowledge to every chocolatier, or chocolate manufacturer.

LikeLike