The transition from “Craft” chocolate (small-batch melangeurs) to “Commerce” (continuous industrial throughput) is not a matter of buying larger versions of small machines. It is a fundamental shift in the physics of particle suspension and thermal management. When an operation attempts to scale to a 500kg/day or 10 TPD (Tonnes Per Day) capacity, they often fall into the “Scaling Trap”—expecting linear performance from non-linear thermodynamics. To bridge this gap, we must look beyond vessel thickness,the shaft diameter, the motor capacity and into the structure of the machinery itself. In an earlier post we discussed in brief about the challenges from moving From Craft to Commerce. If you have not read it, do go through here. In this article, we want to discuss in detail about the challenges.

Thermodynamic Divergence: Surface-to-Volume Ratios

In a 5kg batch, heat dissipation is easily managed via ambient exposure. However, as we scale to industrial refining and conching, the Surface Area-to-Volume ratio decreases significantly. In a high-torque ball mill or a five-roll refiner or a conche, the internal friction generates a “Thermal Core” that cannot be dissipated by standard jacketed cooling alone.

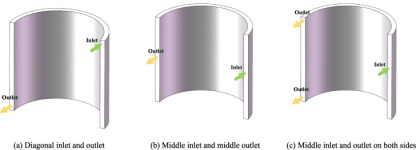

Cooling Jacket in a Ball mill or a chocolate storage tank

For the international plant manager, this creates a Thermal Sync gap. If the cooling logic is tuned for a Swiss climate (average 18°C ambient) but deployed in a tropical hub like Singapore or India (35°C+ ambient), the Delta T (Temperature Differential) between the coolant and the cocoa mass narrows. This results in precursors to “Fat Bloom” at the source—where the cocoa butter crystals (specifically Form V and VI) are thermally compromised before they even reach the tempering stage. To mitigate this, our blueprints specify high-conductivity jackets with increased width between shells providing a 20-30% higher thermal transfer rate than just using standard 304 Stainless Steel.

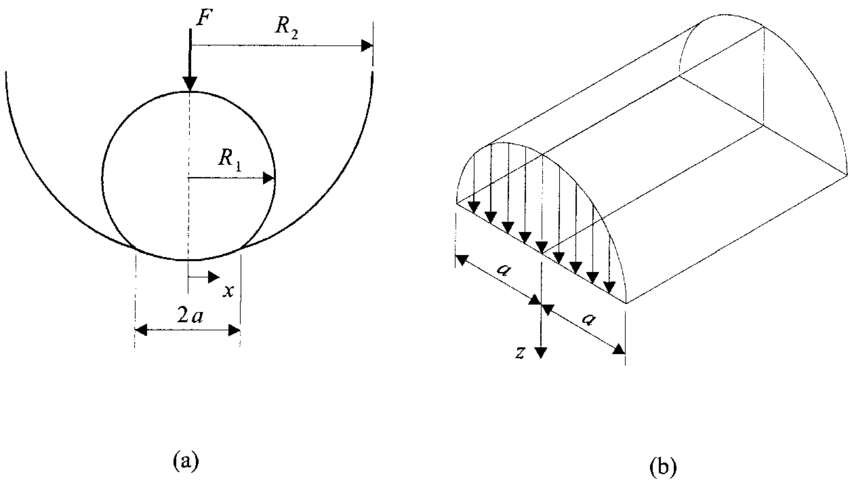

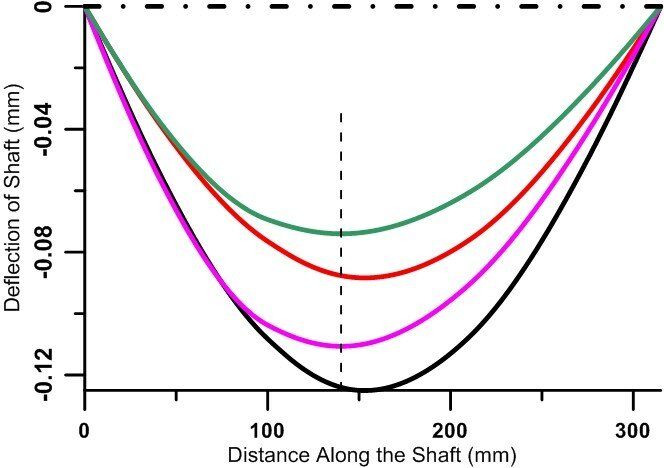

Hertzian Stress in Grinding Media

The “Commerce” scale requires grinding media (balls or rollers) that can withstand sustained Hertzian Contact Stress. In many “lower-cost” machines found in the market nowadays, the metallurgy of the grinding balls or rollers is often a standard Grade 304 or 316 stainless steel. While “Food Grade,” these materials lack the Rockwell Hardness (HRC) required to prevent “Micro-Spalling.”

Hertzian Stress

Micro Spalling

Micro-spalling is the silent killer of chocolate quality. As the cocoa solids are refined, the abrasive nature of the sugar crystals (which are harder than mild steel) creates wear on the grinding surfaces. If the metallurgy is not specifically hardened—typically requiring a high-chromium alloy (HRC 58-62) or specialized induction heat treatment—microscopic metal particles enter the suspension. This doesn’t just affect food safety; it changes the Rheology of the chocolate. Micro-metallic contamination acts as a catalyst for oxidation, shortening shelf life and creating a “metallic” off-note that sophisticated palates in the EU or US will detect instantly.

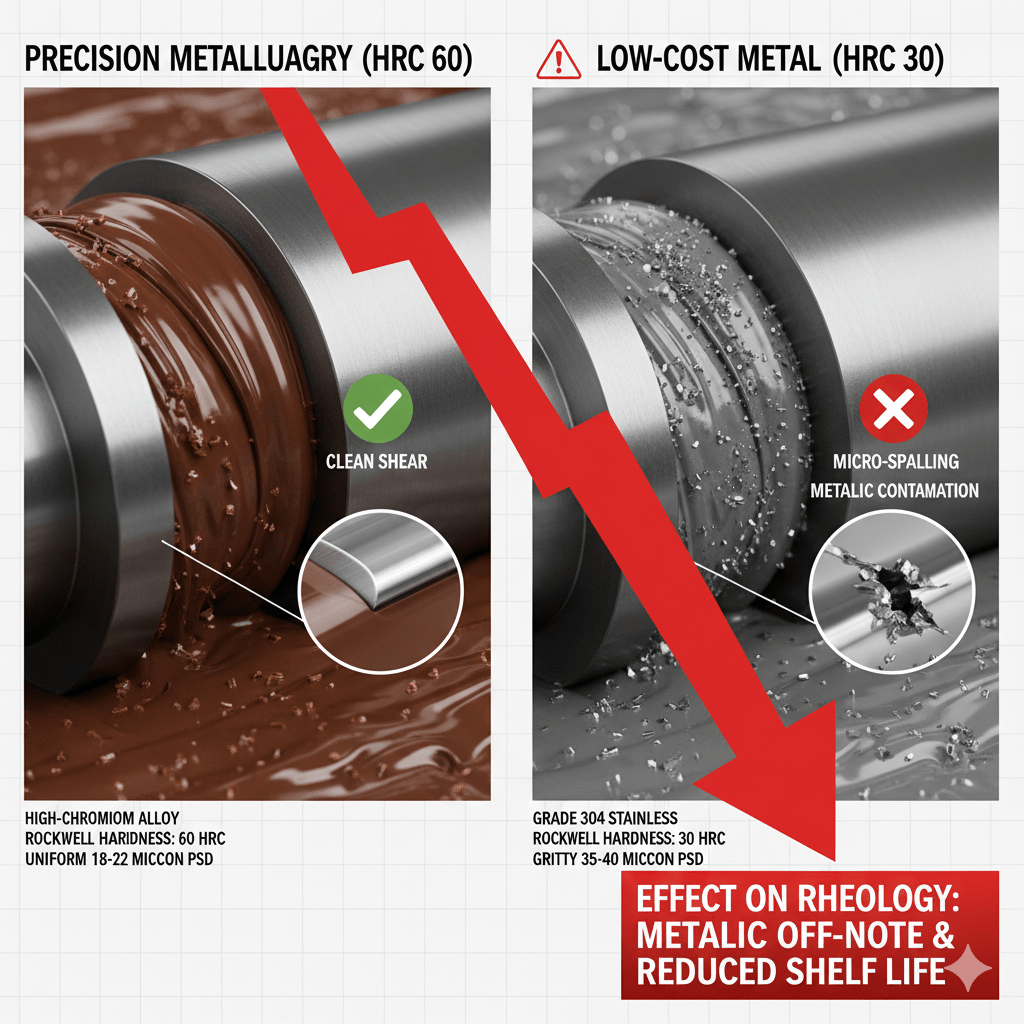

Torque Stability and Shaft Deflection: The 1mm Failure

In a 500kg/day continuous system, the viscosity of the mass creates immense back-pressure on the main drive shaft. At this scale, we must account for Shaft Deflection and Torsional Rigidity. Standard craft machinery often uses over-the-shelf bearings and mild-steel shafts. Under industrial loads, even a 1mm deflection in the shaft alters the “Nip Gap” between the rollers or the clearance in the ball mill.

Deflection against distance along the shaft

This can result in inconsistent particle size distribution (PSD). Instead of a smooth 18-22 micron finish, you get a “gritty” tail of 35-40 micron particles. To achieve the consistency demanded by global standards, the machinery must utilize High-Tensile Alloy Steel (such as EN24 or 4140) for the drive components. These alloys are through-hardened and tempered to ensure that the mechanical tolerances remain stable even as the mass viscosity peaks during the “Dry Conching” phase.

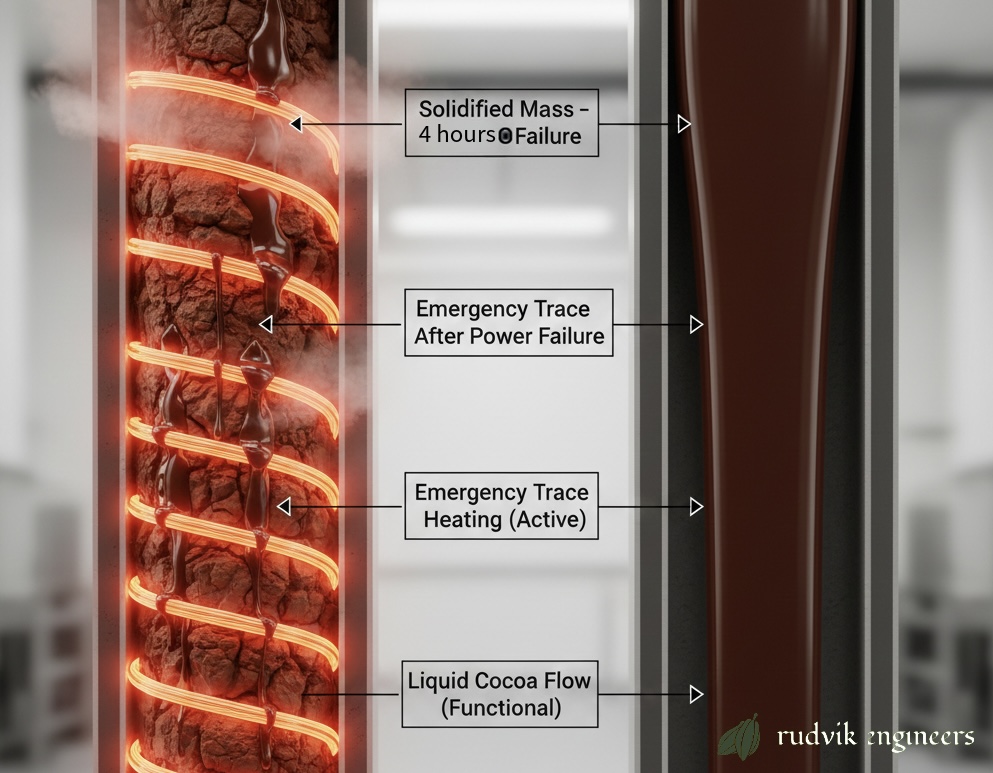

The “4-Hour Rule” and Utility Synchronization

One of the most critical aspects of the Rudvik Engineers blueprint is the “4-Hour Rule.” In a scaled factory, cocoa liquor solidification is the primary cause of multi-day shutdowns. If the power fails or the utility sync (steam/hot water) drops, you have a four-hour window before the cocoa mass in the pipes turns into a solid brick.

The Rudvik 4 hour rule to save your chocolates from solidifying

Precision engineering requires a Redundant Thermal Logic. This means designing the piping with specialized “Trace Heating” and ensuring the metallurgy of the valves can handle the expansion and contraction of rapid reheating. We integrate Emergency Utility Backups in our Blueprint that maintains the jacket temperature even when the main grinders are offline, preventing the “Seizure Cycle” that destroys gearboxes during a forced cold-start.

Vibration Analysis and Harmonic Dampening

As we move toward 10 TPD, the rotational speed of the refining cylinders (up to 300 RPM) creates harmonic vibrations that can lead to Fatigue Failure in the machine frame. Small-scale machines are often bolted to the floor to hide these vibrations, but at the “Commerce” scale, the frame itself must be engineered with Grey Cast Iron (FG260 grade) for its superior natural dampening properties.

Using fabricated mild-steel frames leads to “resonance,” which causes the grinding media to “chatter.” This chatter creates flat spots on the rollers, leading to an uneven “grind profile” and frequent downtime. A true industrial blueprint accounts for the Natural Frequency of the machine to ensure 24/7 operation without structural degradation. We utilize Finite Element Analysis (FEA) to ensure that the machine’s operating frequency stays 20% away from its resonant frequency.

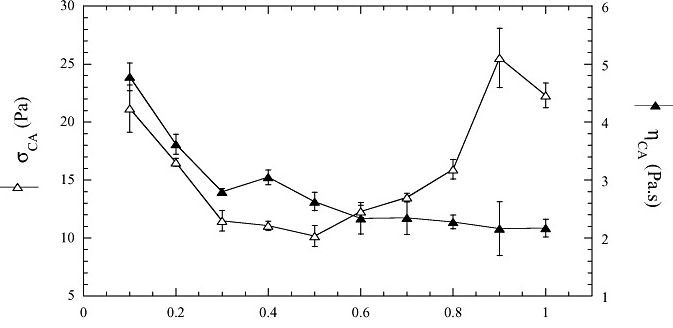

Rheological Control: The Casson Model in Practice

For the 10 TPD operator, understanding Plastic Viscosity and Yield Stress is mandatory. Chocolate is a non-Newtonian fluid. At high shear rates (inside the refiner), it behaves differently than at low shear rates (inside the pump).

Viscosity vs Yield Stress graph

Our industrial strategy utilizes the Casson Model to define the “Flow Point” of the mass. If the metallurgy of the pump impellers is too soft, the abrasive nature of the cocoa particles will increase the clearance between the impeller and the housing. This loss of “Volumetric Efficiency” causes the pump to work harder, generating more heat, which in turn causes the cocoa butter to separate. We suggest utilizing Hard Chrome Plating or Gas Nitriding on high-wear pump components, ensuring that the flow rate remains constant over 10,000 hours of operation, maintaining the precise pressure required for the tempering units. A separate cost analysis has to be done in advance to include this type of coating in pump.

The “Cold-Start” Paradox: Viscosity vs. Metallurgy

A major failure point in scaling up is the “Cold Start.” When the machine is started with solidified or high-viscosity mass, the initial torque required is exponentially higher than the running torque. Without High-Load-Capable Gearboxes and specialized Thermal Pre-heating Logic, the mechanical stress leads to “Shear Failure” in the drive keys or motor couplings.

Precision machining in this context means using gearboxes with Case-Hardened gear teeth profiles and the coupling tolerances to handle this 300% surge in starting torque without plastic deformation. We recommend Helical-Bevel gear units rather than standard worm gears to ensure a 96% efficiency rate, which reduces the total energy cost of a 10 TPD plant by nearly $12,000 annually.

Synchronization of Thermal Profiles

For a 10 TPD plant, the synchronization between the Roaster’s exit temperature and the Grinder’s entry temperature is critical. If the cocoa nibs enter the grinding stage too hot, the friction of the mill will push the mass beyond the “Degradation Point” for volatile aromatics—the delicate floral notes of fine-flavor cacao.

The “Blueprint” for this scale requires a Closed-Loop Thermal Feedback System. The coolant flow rate must be in tune with the mass viscosity; as the chocolate thickens, the torque increases, the heat rises, and the cooling must pre-emptively adjust. This level of Thermal Logic—predicting the heat before it happens—is what separates a “machine owner” from a “process master.” We suggest using PT100 sensors embedded into the grinding surface to capture “Flash Heat” that traditional external sensors miss.

ReactiveMaintenance : The Cost of Ignorance

Finally, the “Commerce” scale demands a different maintenance philosophy. In small batches, you fix things when they break. At 10TPD, you must utilize Predictive Maintenance. This includes periodic Ultrasonic Testing (UT) of the main shafts to detect sub-surface cracks before they lead to a catastrophic snap.

The Rudvik Engineers strategy provides a Machinery Matrix that lists the expected wear-life of every critical component based on the HRC of the metal and the sugar-to-fat ratio of the recipe. By replacing a $50 bearing at the 5,000-hour mark, you prevent a $5,000 gearbox failure at the 5,001-hour mark. This is how we reclaim the 40–50% “Integration Premium” typically charged by global turnkey vendors.

The Conclusion for the Global Stakeholder

You may be auditing a plant in Singapore or designing a new line in the US, the transition to “Commerce” is a commitment to Materials Science. You cannot solve a metallurgy problem with a software update, and you cannot solve a thermal logic problem with a larger motor.

Precision at the industrial scale is the result of aligning the Coefficient of Thermal Expansion of your machinery parts with the Rheological requirements of the cocoa bean. When these two are in synchronisation, the machine disappears, and only the product remains. This is the precision manufacturing of chocolate.

The 10 TPD Cocoa Commerce Blueprint:-Ready to transition to full-scale industrial production? Secure the complete engineering blueprint for a 10 Tons Per Day cocoa butter and powder facility. Includes Machinery Matrix , utility synchronisation, milestones and The Rudvik Hybrid Framework which can save you 8M USD in Capex.

Book Your Industrial Technical Discovery Session:- Facing inconsistent particle size or thermal shutdowns? Book a 45-minute deep-dive session with us to diagnose your specific scaling dilemmas. We analyse your current plans, machinery and provide immediate corrective logic.

India :- Rs. 7499/-

International:- USD 169/-

Before you scale, identify the ‘Hidden Seizure Points’ in your current line. Download our Technical Audit Checklist.