A lot of hardwork, planning and meticulous timing goes into making chocolates. The chocolate maker wants nothing but the chocolate they have put so much work in , to turn out delicious , melt in the mouth and silky for the person enjoying those chocolates. However, nothing pains the chocolatier more when the chocolate shows signs of trouble. Trust us, we have been there and it is harsh and demotivating. A thin white film on the chocolate , either slippery or powdery which seems to ruin all the hardwork.

We are here to let you know that please do not despair. It is the most common problem which happens in both pure and compound chocolates. The first step in removing these white films is understanding what these chocolate defects are and the root cause for them. At Rudvik Engineers we have seen it all and in this article we will try to demystify, troubleshoot these unwanted defects in your otherwise sublime chocolates.

What is “Bloom” and Why Does it Happen?

“Bloom” is the general term for the unwanted white or grayish film that can appear on the surface of chocolates. It can be broadly categorized into two main types: fat bloom and sugar bloom. Both of them are signs that your chocolate’s integrity has been compromised, though their origins and solutions differ significantly. In this article we will focus on fat bloom.

Fat Bloom:- The slippery culprit

Appearance :- It appears as a dull, grayish, or white powdery film that makes the chocolate appear old or stale. It feels greasy to the touch, and the chocolate loses its characteristic snap and shine.

Reason:- What is happening here is that the cocoa butter present in the chocolate is moving to the surface due to the rearrangement of the crystalline structure of the chocolate. We have explained about the crystalline structure of the chocolate and the best variant which Beta V where the chocolate is most stable in our earlier article …Understanding Fats in Your chocolate – Part 2.

As stated in the above article Cocoa butter can exist in several different crystal forms (polymorphs also known as polymorphism in chocolates). When chocolate is improperly tempered, or exposed to fluctuating temperatures, the unstable cocoa butter crystals migrate to the surface and recrystallize into a larger, less desirable form (Form VI), which scatters light and appears white. Think of it like a beautiful brick wall where some bricks (fat crystals) have started to push their way out and create an uneven surface.

Common Causes of Fat Bloom

Improper Tempering

The most common of all reasons of Fat bloom is improper tempering. If the chocolate has not went through the proper temperature cycle to attain the Beta V crystalline structure, any further temperature difference can break the weak structure and cocoa butter can migrate to the surface , causing Fat Bloom. Read more about Chocolate tempering in our article Why chocolate tempering is a must.

Storage Conditions

We have already discussed about temperature fluctuations during tempering. However even when a chocolate is tempered correctly, improper storage conditions can push the cocoa butter on the surface. This can happen when the frequency of temperature changes(even a small change of 2-3 °C) during storage are very high.

Incompatible Fats

In the case of Compound chocolates, if the fat used or the blend of fats used are incompatible with the cocoa particles or sugar particles, these fats can then move to the surface , causing Fat bloom. Read more about the compatibility of fats in chocolates in our article Understanding Fats in your chocolate- What you need to know.

Particle Size Distribution

![Chocolate PSD- Credit :-Determination of chocolate melting properties by capacitance based thermal analysis (CTA) - Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Particle-size-distribution-in-chocolate-at-different-times-during-refining_fig3_320961368 [accessed 10 Aug 2025]](https://rudvikeng.in/wp-content/uploads/2025/08/particle-size-distribution-in-chocolate-at-different-times-during-refining.gif.png?w=388)

Chocolate PSD- Credit :-Determination of chocolate melting properties by capacitance based thermal analysis (CTA) – Scientific Figure on ResearchGate. Available from: https://www.researchgate.net/figure/Particle-size-distribution-in-chocolate-at-different-times-during-refining_fig3_320961368 [accessed 10 Aug 2025]

In one of our previous articles , The importance of micron size in chocolates we discussed about how much percentage of particle in the chocolate are around or less than the required particle size. This is called Particle Size Distribution , PSD. A sweet spot for the PSD is that 90% of particles present in the chocolate should be between 18-22 microns. If you keep reducing the particle size or rearranging the PSD, the chocolate will sure become more homogenous, but the surface area of the total particles present will increase. This can create a greater interlocking between the particles, which can inturn increase the chances of cracks to develop , from where the fat can move to the surface.

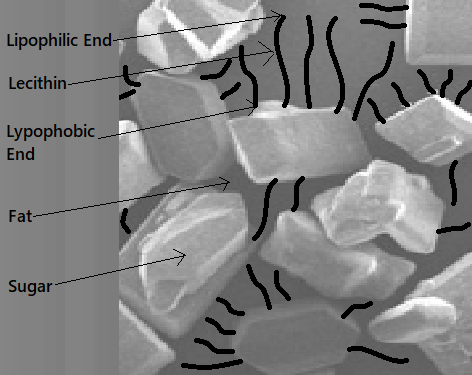

Emulsifiers

Emulsifiers are one of the key ingredients which hold together cocoa particle, sugar and fat. You can read more in our previous article Emulsifiers-Sweet secret to perfect chocolate texture. However the type of emulsifier being used, its source and its concentration also affects its compatibility with the fat being used , which if used incorrectly can cause the Fat to migrate.

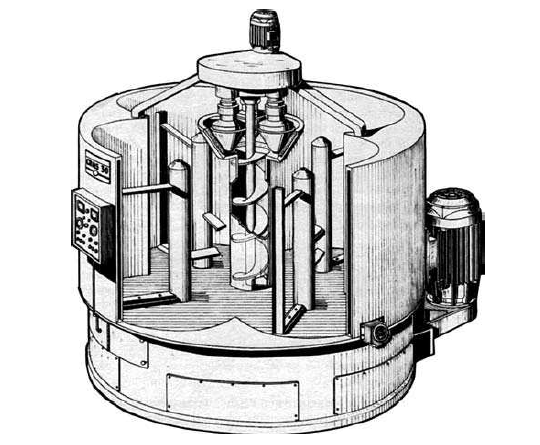

Porosity

The internal pore structure of the chocolate matrix can also give rise to FAT migration. This can happen during Refining, grinding or conching stage.

Some solutions

Correct Tempering

This is a no brainer. The correct temperature cycle has to be done, which is different in case of different chocolates.

For milk chocolates

Complete Melt out – 45-50 °C

Controlled and Rapid Cooling – 27-29 °C

Reheating- 29-31 °C

For Dark Chocolates

Complete Melt out – 50-55 °C

Controlled and Rapid Cooling – 28-30 °C

Reheating- 31-32 °C

This cycle alongwith continuous agitation ensures that the correct Beta V crystals are formed which give rise to a stable, shiny chocolate.

Storage Conditions

A consistent temperature range which is narrow, has to be maintained, ideally 18-20 °C, with minimal fluctuations

Humidity must be kept between 50-55 %.

Advanced packaging can also be used like barrier films.

Incompatibility with Fats

Using high quality cocoa butter with a consistent triglyceride profile.Why is it needed you ask? Well if you have gone through our earlier article as mentioned above, triglycerides with similar melting and crystallizing behaviors help maintain stable fat crystals which is the Beta V. Too much variability in triglyceride types can interfere with proper crystal formation, leading to unstable crystals that are more prone to migrate to the surface, causing Fat bloom.

When making compound chocolates, any fat apart from cocoa butter must be of similar melting point and triglyceride profile. One can also use the method of fractionating the fats which enriches stable triglycerides. In case of using a filling in a chocolate shell, what works is a barrier fat between the filling and the chocolate which can help stop the fat inside the filling or insie the chocolate to migrate to the surfaace.

In the next article we will talk about Sugar Bloom, its causes and some solutions.

We hope the above article has helped you in some way in your chocolate making journey.

Book a 1 hour Technical Strategy Session today.

For India- Rs. 2499/-

Outside India:- USD 39/-