Any food product in today’s world, before hitting your local grocery store shelf or finding a place on your favorite e-commerce platform, must declare the shelf life or best before period of the product, which tells the general consumer , if the said product is safe for consumption or not.

Chocolate and chocolate products are no different and they too must display , clearly, along with their ingredient list, the energy details, manufacturing date and the total shelf life ot best before period. It may range anywhere from a day to 24 months depending upon the type of chocolate or chocolate product.

However with chocolates, determining the shelf life and the ways to do so become a bit confusing and not at all absolute. In this article we would like to point out why shelf life in chocolates is tricky, some points to help determine the shelf life of your chocolate product and factors to consider during the testing phase of shelf life of your chocolate product.

Why Chocolate shelf life is tricky?

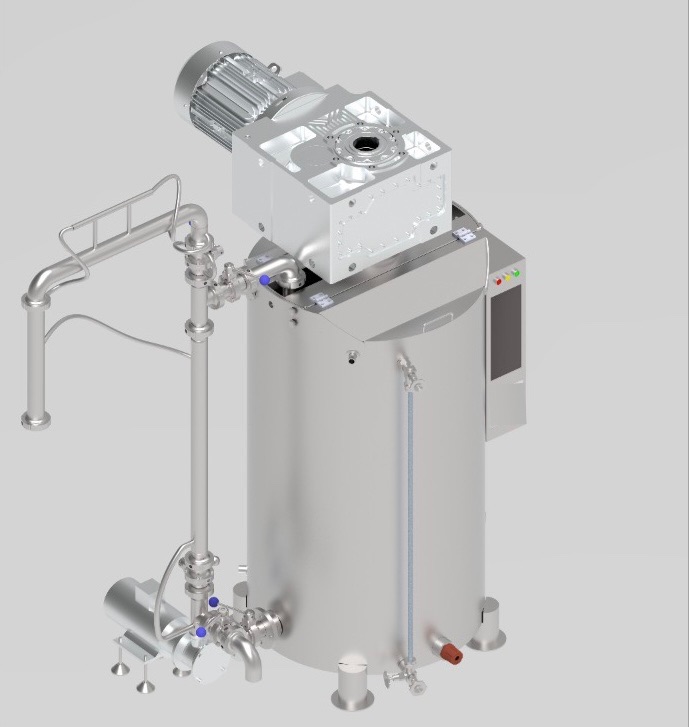

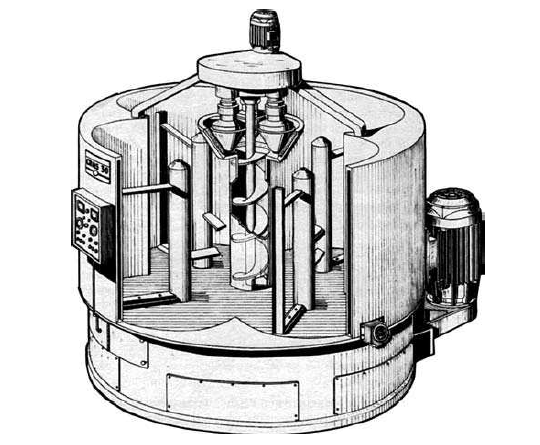

We all know to some extent when there is moisture present in a food product, it becomes a breeding ground for mold, bacteria and germs. That is the reason why the dehydrated versions of your favorite fruit , seem to do well, in terms of shelf life. And we also know from many of our previous article here, that from the roasting of fermented cacao beans to the grinding, conching, refining,(read our previous article on ball mills, conches and roll refiners here) all these processes ensure that there is a minimal amount of moisture/water present in the chocolate. We may also remember from our previous articles that any amount of water addition(read about importance of viscosity in chocolates) into the chocolate during the chocolate manufacturing process, either knowingly or unknowingly can have devastating consequences and damage the whold batch of your chocolate.

So if all the processes during the manufacturing of chocolate aim to lessen the water percentage present in chocolate and there is minimal amount of water, then how is there going to be contamination of chocolate due to germs/bacterias and how is the shelf life decided? Are there other factors at play here which affect the shelf life of the chocolate? Spoiler Alert:- There are.

Moisture

Even well dried cacao beans and cocoa powders have some amount of mositure present in them. Note that we have always mentioned negligible, minimal amount of moisture. So, apparently it is not zero. In cacao beans a moisture percentage of less than 7.5% is accepted. In cocoa powders, depending upon the grade of the cocoa powder, amoisture percentage of 2-4% is acceptable. If a chocolate is made just from cacao beans, cocoa butter, sugar and emulsifier as is in the case of dark chocolates, the shelf life is considered on the higher side , 18-24 months.

Cocoa butter has higher stability and less prone to oxidisation , so the dark chocolate variants have a higher shelf life. This leads us directly to the type of fat used for making the chocolates. If instead of cocoa butter, vegetable fats or blends of vegetable fat are used, the shelf life decreases , which can be any where between 12-18 months. As these fats, which may be used as Cocoa Butter Substitutes(CBS), cocoa butter enhancer(CBE) or cocoa butter replacer(CBR), have higher susceptibility of oxidation, the shelf life decreases.

Now if we move towards milk chocolates, the addition of milk fats and other additives also drammaticaly reduce the shelf life of the chocolate as milk fats are likely to have rancidity and off flavors.

Moving towards chocolates with fillings, nuts or inclusions, these all affect the shelf life of chocolate product as a whole as these fillings, nuts or inclusions are more perishable.

Storage conditions

Apart from all of the above the storage conditions in which the chocolate are stored or transported also effect the shelf life. An ideal temperature of 15-18 ℃ (59-64°F) with low humidity(less than 55%) is great for storage of chocolate products resulting in a higher shelf life and improved consumption experience. Higher temperature can cause fat to migrate resulting in Fat Bloom and higher humidity can cause sugar to migrate resulting in sugar bloom.

Prolonged exposure to light and air can accelerate oxidation specially in milk and white chocolates with fillings, nuts or inclusions. A good solution for these problems are to invest in higher quality packaging with nitrogen(as an inert gas) cushioning which can prevent air and light entry into the chocolate product.

Methods to determine shelf life

– Sensory Testing– A sensory evaluation of taste, texture , looks is done to maintain a base line of the chocolate product.

– Accelerated Shelf Life Testing:- The chocolate product is exposed to higher temperatures and higher humidity for a shorter period of time, simulating wear and exposure at low temperature and low humidity for a longer period of time. This testing method gives an almost accurate picture of how the chocolate will perform in real world situations and the shelf life of the chocolate.

– Microbial testing:- This test is done for Colony Forming units and the chocolate is tested for molds, bacterias or germs.

– Ingredient Analysis:- All the individual ingredients and their proportion in the chocolate product are tested. Milk fats , vegetable fats oxidise faster than cocoa butter alone and hence have lower shelf life. Inclusions, nuts like hazelnuts, almonds are perishable faster, limiting the total shelf life of the chocolate product.

Some solutions to enhance shelf life

– Using CBS, CBE or CBR which have a lower oxidisation rate

– Using emulsifier. In one of our previous articles we mentioned how emuslifiers bind the cocoa and sugar particles with the fat globules more efficiently ( read the article here)resulting in a more stabilised chocolate. This stability which is achieved due to the inherent nature of the emulsifiers, also increases the shlef life of the chocolate.

– Investing in good quality packaging machine and packaging materials. As mentioned before, using high quality packaging material which inhibits the passage of light and air , increases the shelf life as it slows the degradation process. Using nitrogen purging also creates a barrier between the elements of the atmosphere and the chocolate product , thereby increasing the shelf life of the chocolate.

Conclusion

Please note that , dark chocolate or variants of dark chocolate are never actually bad for consumption even after there best before date. This date signifies that the quality , taste and texture which is promised by the manufacturer is at best when the chocolate product is consumed within the said time period.