Ah, chocolate – the ultimate comfort food! Whether you’re feeling down in the dumps or just want a sweet treat, nothing beats a chocolate bar or a warm mug of cocoa. But have you ever stopped to wonder what makes chocolate so deliciously decadent? Well, my friend, let me tell you – it’s all thanks to the fats used in its creation apart from the magical ingredient, that is cocoa!

Yes, you heard that right – fats are a crucial ingredient in chocolate, and they play a major role in determining the taste, texture, and overall quality of your favorite chocolate treats. But not all fats are created equal, and there are several different types of fats used in chocolate production. In this article, we’ll take a closer look at these different fats, how they’re beneficial, and why they’re so darn tasty!

Cocoa Butter- The one and the only

First up, we have cocoa butter – the star of the chocolate show. Cocoa butter is a type of vegetable fat that is extracted from cocoa beans, and it’s the main fat used in high-quality chocolate products. It’s known for its smooth, creamy texture and delicate flavor, and it’s what gives chocolate its characteristic melt-in-your-mouth feel.

Cocoa butter has a unique fatty acid composition that gives it a melting point that is close to body temperature, which allows it to melt in the mouth and give chocolate its signature smooth texture.

Cocoa butter is a triglyceride, which means it is made up of three fatty acids attached to a glycerol molecule. When cocoa butter is melted, these fatty acids are dispersed randomly throughout the liquid.

As the chocolate cools and begins to solidify, the cocoa butter starts to crystallize. The size and shape of the cocoa butter crystals that form affect the viscosity of the chocolate. Small, evenly sized crystals result in a smooth texture and lower viscosity, while larger crystals create a more grainy texture and higher viscosity.

But cocoa butter isn’t just delicious – it’s also beneficial for your health! Unlike other types of fats, cocoa butter is high in saturated and monounsaturated fats, which have been shown to raise HDL (good) cholesterol levels and lower LDL (bad) cholesterol levels. Additionally, cocoa butter contains antioxidants and flavonoids that have been linked to improved heart health, reduced inflammation, and even lower rates of cancer and neurodegenerative diseases.

Milky is the way

Next, we have milk fat – a type of animal fat that is used in many milk chocolate products. Milk fat is derived from milk and is known for its rich, creamy flavor and smooth texture. It’s often used in combination with cocoa butter to create a perfect balance of flavor and texture in chocolate products.

Milk fat contains a high amount of conjugated linoleic acid (CLA), which has been linked to improved immune function, reduced inflammation, and even weight loss. Additionally, milk fat is a good source of vitamins A and D, which are essential for healthy skin, bones, and immune function.

Milk fat is also known as butterfat, and it contains a mixture of saturated, monounsaturated, and polyunsaturated fatty acids. Milk fat can be used in chocolate in a variety of forms, including milk powder, condensed milk, and cream.

Breaking the mold-Vegetable Fats

Third on our list is vegetable oil – a type of fat that is commonly used in chocolate products. Vegetable oils such as soybean, palm, and canola oil are often used as an inexpensive alternative to cocoa butter, and they can impact the taste and texture of chocolate products.

Vegetable fats have some benefits when used in moderation. Some types of vegetable oils are high in omega-3 and omega-6 fatty acids, which are essential for healthy brain function and may help reduce the risk of heart disease and stroke.

These fats are derived from plant sources, such as soybeans, palm trees, and coconut. Vegetable fats can be used as a replacement for cocoa butter in some chocolates, as they are less expensive and more readily available. However, some types of vegetable fats can have an impact on the taste, texture, and quality of chocolate, and they may not provide the same health benefits as cocoa butter.

Finally, we have trans fats – a type of fat that is typically found in processed foods such as baked goods, fried foods, and margarine. Trans fats are created through a process called hydrogenation, which turns liquid oils into solid fats. They are known for their negative impact on heart health and are considered one of the unhealthiest types of fats.

Luckily, trans fats are not commonly used in chocolate production. However, it’s important to check the ingredients list on chocolate products to ensure that they don’t contain any trans fats.

Emulsifiers

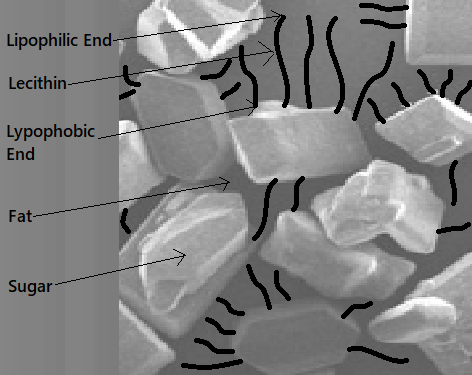

Emulsifiers are substances that help to mix water-based and oil-based ingredients together. In chocolate, emulsifiers are used to keep the cocoa butter and other ingredients from separating, which can affect the texture and appearance of the final product. Common emulsifiers used in chocolate include soy lecithin and polyglycerol polyricinoleate (PGPR). Read our in depth post about emulsifiers- Emulsifiers: The Sweet Secret to Perfect Chocolate Texture.

Why Fats?

Now that we’ve explored the different types of fats used in chocolate, let’s take a closer look at how they affect the viscosity, mouthfeel, and snap of chocolate. Viscosity refers to the thickness and flow of a liquid. In chocolate, viscosity is an important factor that affects the texture and mouthfeel of the final product. The amount and type of fat used in chocolate can affect its viscosity.

Cocoa butter has a unique fatty acid composition that gives it a melting point that is close to body temperature. This means that cocoa butter can melt in the mouth and provide a smooth, creamy texture. However, if too much cocoa butter is used in chocolate, it can become too thin and runny. On the other hand, if too little cocoa butter is used, the chocolate can be thick and difficult to work with.

Other types of fats, such as vegetable fats, can also affect the viscosity of chocolate. Vegetable fats have a different fatty acid composition than cocoa butter, which can affect their melting point and texture. Some vegetable fats, such as palm oil, have a high melting point and can make chocolate thicker and harder to work with. Other vegetable fats, such as coconut oil, have a lower melting point and can make chocolate thinner and more runny.

How does it affect the viscosity and other parameters?

The topic of whether the addition of fats, especially vegetable fats, increases or decreases the viscosity, is a whole subject on its own and would discuss about it in a future post. Meanwhile, we would implore you to read our article –The importance of Viscosity in Chocolates.

Conclusion

So, there you have it – a closer look at the different types of fats used in chocolate production and their various benefits. While it’s true that some types of fats are healthier than others, it’s important to remember that moderation is key.